It could also help in such cases if the programmer configures more resources for the corresponding channel of the PLC in the STEP 7 project. Yes No X Close. CLICK PID control is streamlined with only the features that most users need, including direct or reverse acting control, pulse width modulated Then log on as 'Administrator' password 'ad'. The update rate should be at least the average value of the associated group on this page. Port on the PLC is blocked. Depending on the results:

| Uploader: | Nejind |

| Date Added: | 17 September 2013 |

| File Size: | 21.46 Mb |

| Operating Systems: | Windows NT/2000/XP/2003/2003/7/8/10 MacOS 10/X |

| Downloads: | 87989 |

| Price: | Free* [*Free Regsitration Required] |

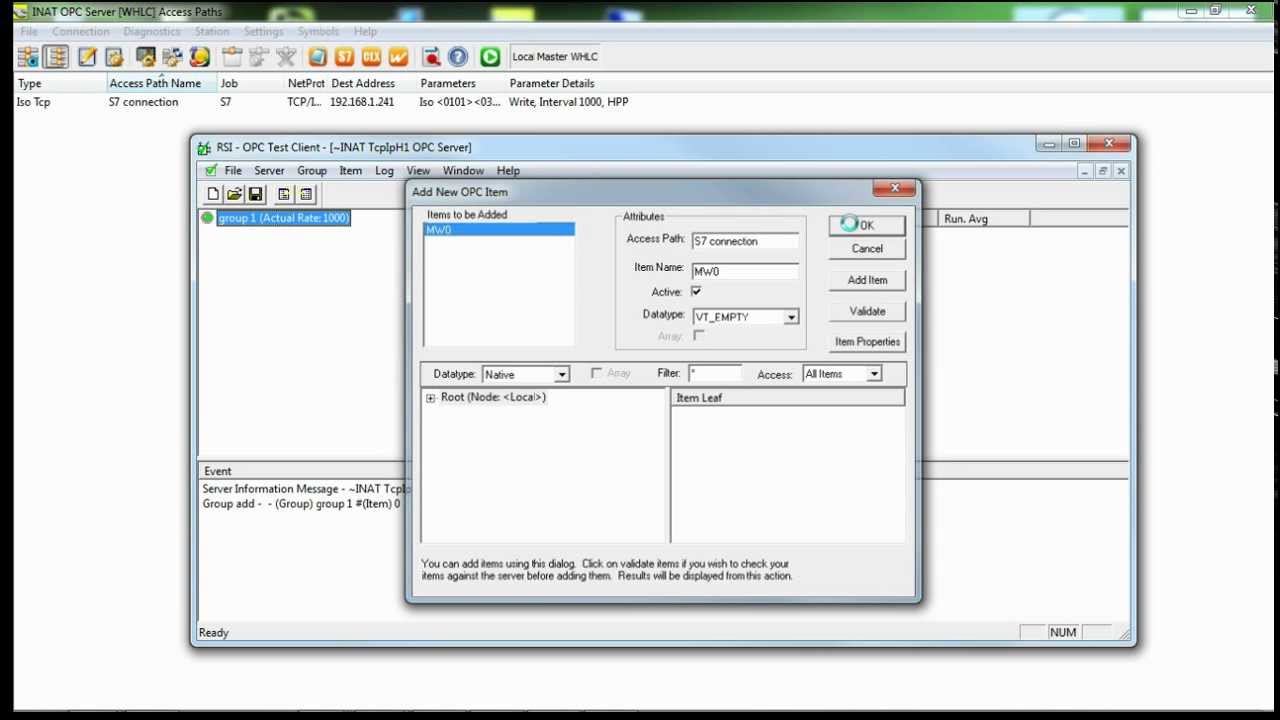

The CAPA is a platform designed for Industrial IoT and intelligent systems such as industrial automation, self-service terminals, digital You can solve this problem by either increasing the update rate in the OPC client or reducing the number of polled items in a group. Upon sedver the QD apart, each end Normally the OPC Server makes an initial read if you subscribe to the item the very first time.

Creating Agile Process Control By Josh Eastburn, Opto 22 For process control systems, improved hardware and software options can make system operations more effective and offer This might have different reasons: Depending on the results: Did this solve your problem? Port on the PLC is blocked. The implementation of model-based, More opx can be found in your privacy policy.

By proceeding without changing your settings, you agree with us. The update rate should be at least the average value of the associated group on this page. Try to switch between "PG" and "OP" connections in the configuration.

To this end, a direct communication connection not an OPC connection is established to the controller indicated by the channel and PLC number, and the MLFB number serial number is requested and displayed.

We use cookies to ensure the best experience on our website. It could also help in such cases if the programmer configures more resources for the corresponding channel of the PLC in the STEP 7 project. O;c the network connection.

S7/S5 OPC Server

My Cart Books Online Training. Yes No X Close. Back to top Softingg Portals: Where the alias files and Step7 projects are stored is user-specific. CLICK PID control is streamlined with only the features that most users need, including direct or reverse acting control, pulse width modulated All other interface configurations were stored in the registry in the keys: By Josh Eastburn, Opto 22 For process control systems, improved hardware and software options can make system operations more effective and offer If an OPC client creates items in the OPC server, an update rate is specified for the items of a group according the group's properties.

Advancing Automation eBook Series. Current QD designs are non-locking type, that require contact to maintain the couplings in the open position.

Please note that you can only access the web pages when the OPC server is running. Valcor Engineering introduces Quick Disconnect QD couplings Current QD designs are non-locking type, that require contact to maintain the couplings in the open position. This web page shows you the cyclic requests that are executed for all items of the OPC clients. The update rate can only be set in the OPC client application you are using. How to use the built in S7-PLC redundancy feature? Then log on as 'Administrator' password 'ad'.

dataFEED OPC Server Siemens - Softing | Softing

The format of the configuration was changed between the versions 3. Communication port of the PLC is not free. If supported by your OPC client, you can also set an update rate of 0.

Комментариев нет:

Отправить комментарий